Ask for a free demo via contact form

or call +1 704 819 8574

C|PS - Particle suction extraction

Suction extraction extends the test methods for dry and non-destructive component testing.

As a supplementary extraction method to the well-known VDA 19.1 methods of wet extraction or air extraction by blowing off, suction extraction enables the testing of electrical/electronic components or components for e-mobility, e.g. battery systems, in particular.

- C|PS² - The light and compact system for mobile use

- C|PS³apex - The ergonomic complete system with digital control for reliable user guidance

- Large range of accessories and materials, e.g. suction nozzles, analysis materials, spares

- Installation and training services

- After sales service, inspection and maintenance at site

Continue to product page C|PS - Suction extraction systems

Particle monitoring

Monitoring accessories for assessing particle appearance in the production environment, including using particle traps or stamps.

- Particle trap - Particles that settle on the traps become permanently attached to the filter pad.

- The particle stamp collects particles from surfaces and permanently fixes them to the adhesive pad.

- The SEM particle stamp was developed for analyzes with the scanning electron microscope (SEM).

- The stand allows easy placement of the particles traps in different heights.

- The mounting bracket allows the rapid and optimal placement of the particle traps at the desired position.

Continue to product page particle trap and particle stamp...

Assembly Cleanliness

Cleanliness areas as room concepts are supported through special products and systems.

Barrier and marking tapes mark and delimit clean zones (e.g. (SaS1) according to VDA 19.2)

Clean mats for reduction of particle entry by personnel when entering a cleanliness zone (SaS 1) or a cleanliness room (SaS 2) according to VDA 19.2

Glove cleaning system for removal of micro-particles to prevent negative influence of the production process

Particle visualization lamp for visualization of fluorescent particles by UV light - e.g. for inspection in containers, machinery, process chambers, etc.

More....

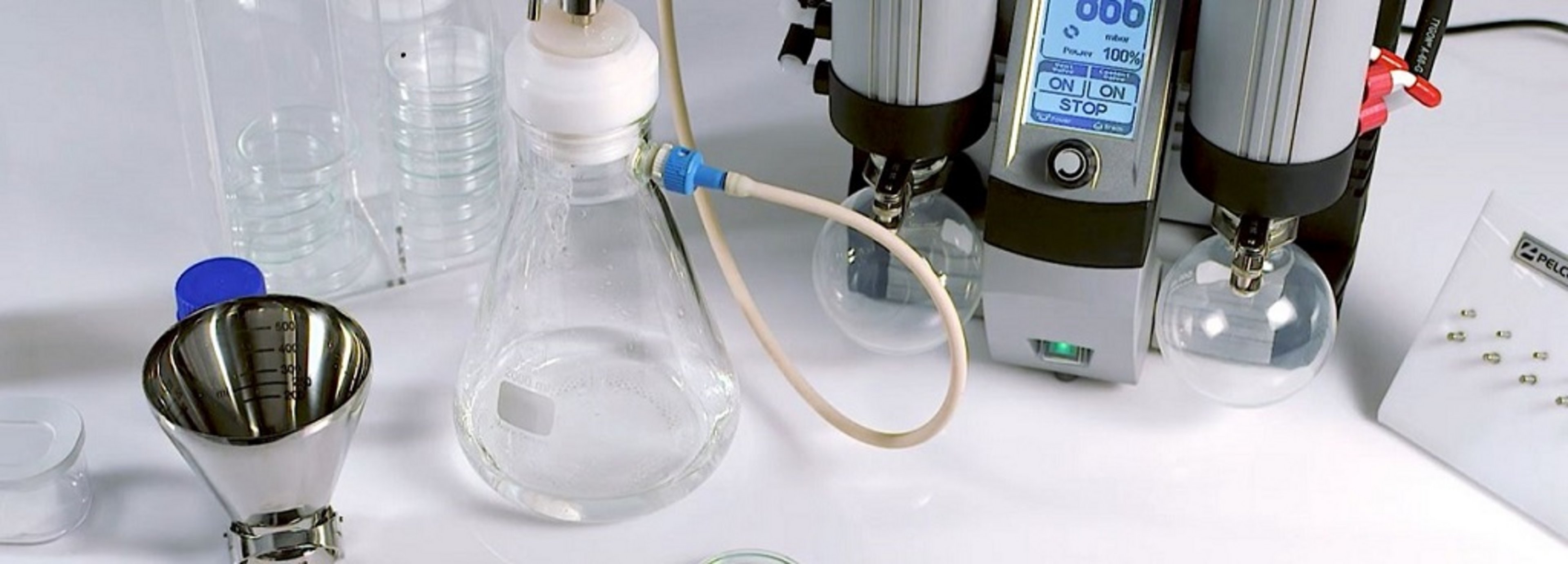

Laboratory equipment and materials

The right laboratory equipment and accessories are deci-sive for the results of the cleanliness test. CleanControlling offers laboratory technology matched to the needs of a cleanliness laboratory.

- Vacuum filtration unit for separation of extracted particles from the analysis of liquid on the analysis filter surface

- Tweezers and clips for clean and safe filter handling and for for gentle handling of components during particle extraction

- Cleanroom coats and caps for protection of the cleanroom from human contamination and clothes

- Filter membranes and accessories and accessories for microscopy

More information

Further information and our entire product range with order numbers and prices can be found in our CleanControlling-eShop.

Newsletter registration