Technical cleanliness: Characterization of materials by IR and SEM/EDX

Technical cleanliness is a decisive factor in modern manufacturing, especially in industries such as the automotive industry, electronics and medical technology. The characterization of materials plays a central role in ensuring technical cleanliness. This white paper examines the materials that can be characterized by infrared spectroscopy (IR) and scanning electron microscopy with energy dispersive X-ray spectroscopy (SEM/EDX).

Characterization by infrared spectroscopy (IR)

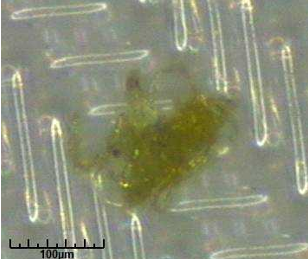

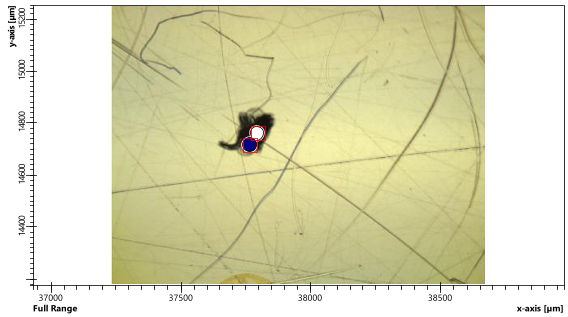

Infrared spectroscopy (IR) is an analytical technique based on the interaction of infrared light with matter. It is mainly used to identify and characterize organic materials. In certain cases, inorganic materials can also be identified using this method.

How IR spectroscopy works:

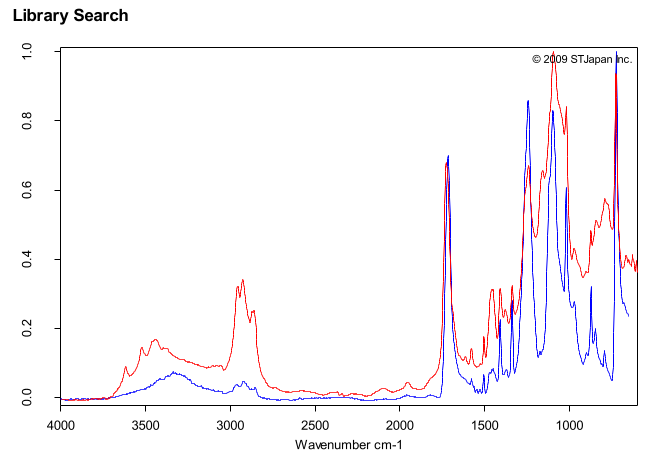

- Principle: IR spectroscopy uses the absorption of infrared light by molecules to analyze their vibrational modes. Each chemical bond in a molecule absorbs infrared light at specific frequencies, resulting in a characteristic spectrum.

- Application: Identification of functional groups in organic compounds, analysis of polymer structures and investigation of impurities.

Typical materials that can be characterized by IR:

- Polymers: polyethylene, polypropylene, polystyrene

- Organic compounds: Hydrocarbons, alcohols, ketones

- Organic materials: Hair, proteins, cellulose, natural fibers

IR spectroscopy - possibilities and limitations

The use of standardized databases makes it possible to quickly and reliably determine the origin of many organic particles. Even better results can be achieved by using the company's own databases. Here, material samples are analyzed during the manufacturing process and compared with the particles found.

Although the use of databases allows particles to be characterized quickly, the evaluation should always be carried out by chemically trained personnel. Particles from production processes are often not available as pure material. Residues of production additives are often found on plastic particles, which leads to a superposition of different IR spectra and thus reduces the correlation with the correct database entry.

Characterization by scanning electron microscopy with EDX (SEM/EDX)

Scanning electron microscopy (SEM) combined with energy dispersive X-ray spectroscopy (EDX) enables high-resolution imaging and chemical analysis of materials. This technique is particularly useful for examining surface structures and determining chemical composition.

How SEM/EDX works:

- Principle: A focused electron beam scans the sample surface and generates various interaction signals, including secondary electrons and characteristic X-rays. These signals are used for imaging and chemical analysis.

- Application: Examination of surface structures, determination of elemental composition and analysis of material defects.

Typical materials that can be characterized by SEM/EDX:

- Metals: aluminum, copper, iron

- Ceramics: Aluminum oxide, zirconium dioxide

- Semiconductors: silicon, germanium

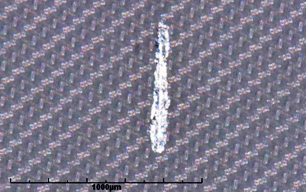

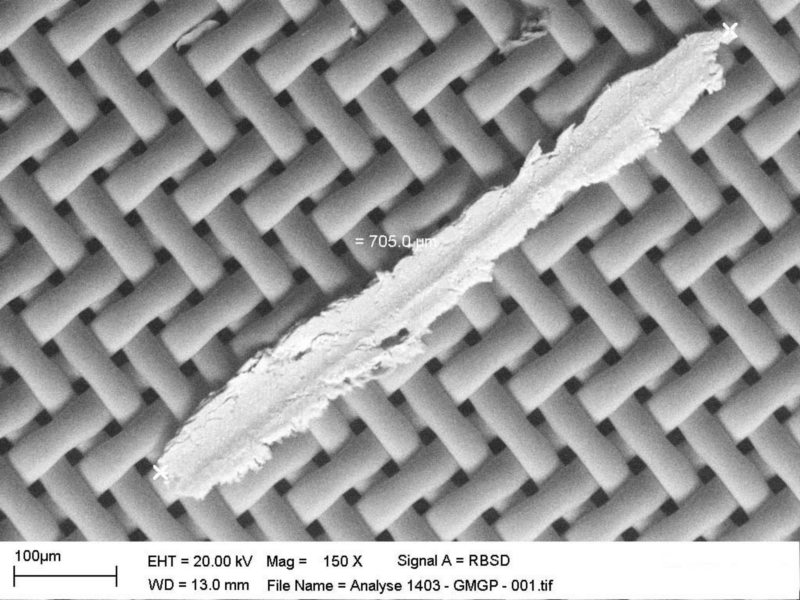

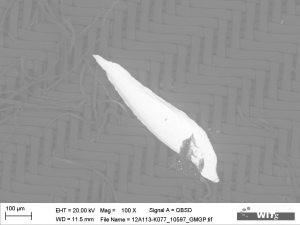

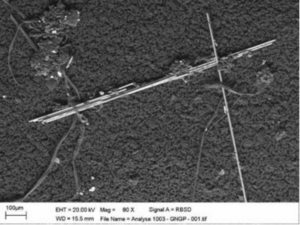

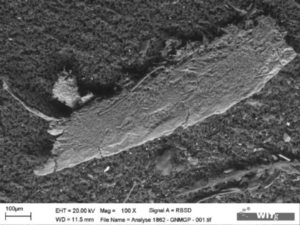

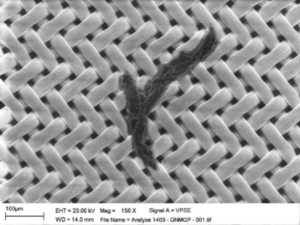

Examples of metallic particles

SEM/EDX analysis - possibilities and limitations

As with IR spectroscopy, the main area of application of SEM/EDX analysis in technical cleanliness is the determination of the material composition of particles. In contrast to IR analysis, however, the molecular structure (and in particular C-H, C-C, C-N or C-O bonds) is not examined. However, as EDX is used to examine the elemental composition and not the molecular structure, specific elements in the particles can be identified and quantified. This enables a detailed analysis of the origin and composition of the particles, which is of great importance for the evaluation of technical cleanliness.

Critical materials in technical cleanliness

In technical cleanliness, there are materials that are particularly critical as they can significantly impair the function and service life of components. These materials include:

- Particles: Metal chips, dust particles

- Chemicals: oils, greases, solvents

- Oxides and corrosion products: Rust, scale

- Fibers: Textile fibers, paper fibers

The most critical are:

- Metal shavings: These can lead to short circuits and mechanical damage.

- Oils and greases: These can impair the adhesion of coatings and adhesives.

- Rust and scale: These can cause corrosion and malfunctions.

Conclusion

Choosing the right analysis technique is crucial for ensuring technical cleanliness. While IR spectroscopy is particularly suitable for the characterization of organic and inorganic compounds, the SEM/EDX technique offers a detailed analysis of the surface structure and chemical composition of metals, ceramics and semiconductors. A deep understanding of materials and their properties contributes significantly to optimizing production processes and increasing product quality.

Sources:

[1] Leitfaden Technische Sauberkeit in der Elektrotechnik - ZVEI

[2] Technische Sauberkeit - Fraunhofer IPA

Newsletter registration