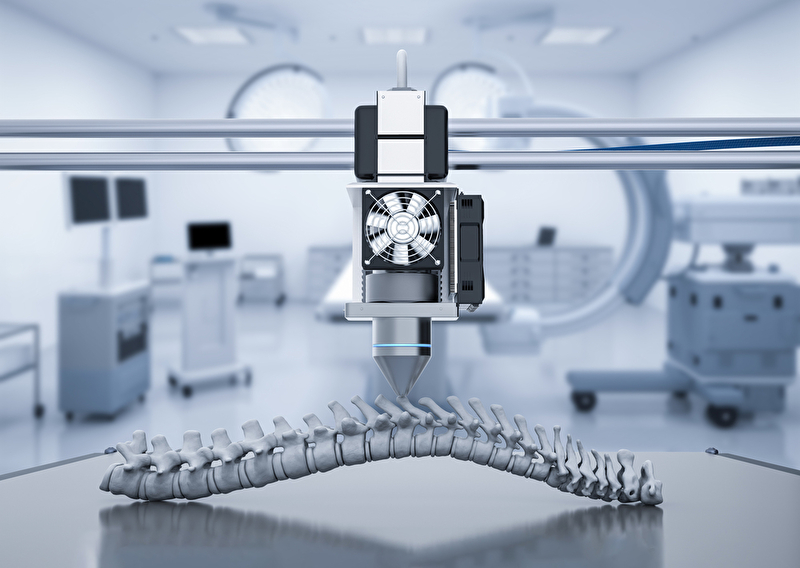

Prototypes of medical devices for chemical characterization?

Chemical characterization is an essential part of the biocompatibility testing of medical devices. It is used to identify and quantify the chemical components of a device to ensure that no harmful substances are released that could endanger the patient's health. A frequently asked question is whether a prototype or a medical device that has not yet been fully developed can be used for this characterization.

Use of prototypes

Testing a prototype can be useful in certain development phases in order to identify and minimize potential risks at an early stage. However, it is important to note that the results of these tests may not be fully transferable to the final product. Differences in materials, manufacturing processes or finishes can affect the chemical composition and therefore biocompatibility.

Necessity of repetition

If the chemical characterization is performed on a prototype, it may be necessary to repeat the test with the market-ready product. This ensures that any changes made during development are taken into account and that the final product meets the required safety standards.

Conclusion

Chemical characterization is a critical step in the biocompatibility testing of medical devices. While prototypes can provide useful information, it is often necessary to repeat the tests on the final product to ensure the safety and efficacy of the device. Manufacturers should therefore carefully consider when and how to integrate prototypes into the testing process to achieve the best possible results.

Newsletter registration