Materials testing: Quality testing of metal bar material

Quality inspection of metal bar stock is critical to ensure that the material is free of defects and voids that could compromise structural integrity. Two common methods for detecting such defects are ultrasonic testing (US) and computed tomography (CT). Both methods have their own advantages and disadvantages, and combining them can lead to significant cost savings.

Ultrasonic testing (US)

Ultrasonic testing uses high-frequency sound waves that are transmitted through the material. These sound waves are emitted by a transmitter and guided through the material. When the waves hit a defect or a cavity, they are reflected and detected by a receiver. The time and intensity of the reflected waves provide information about the location and size of the defects.

A major advantage of ultrasonic testing is its cost efficiency. Compared to computer tomography, ultrasonic testing is significantly cheaper, both in terms of purchasing the equipment and carrying out the tests. Ultrasonic testing can also be carried out very quickly, which makes it particularly suitable for inspecting large quantities of material. Another advantage is the mobility of the UT devices, which are often portable and can be used on site.

However, ultrasonic testing also has its disadvantages. The resolution of ultrasound images is lower compared to computer tomography, which makes it difficult to detect very small defects. The echograms also require a great deal of expertise and experience on the part of the inspecting personnel when evaluating the echograms. The effectiveness of ultrasonic testing can also be influenced by the material properties, such as the grain size of the metal.

Computed tomography (CT)

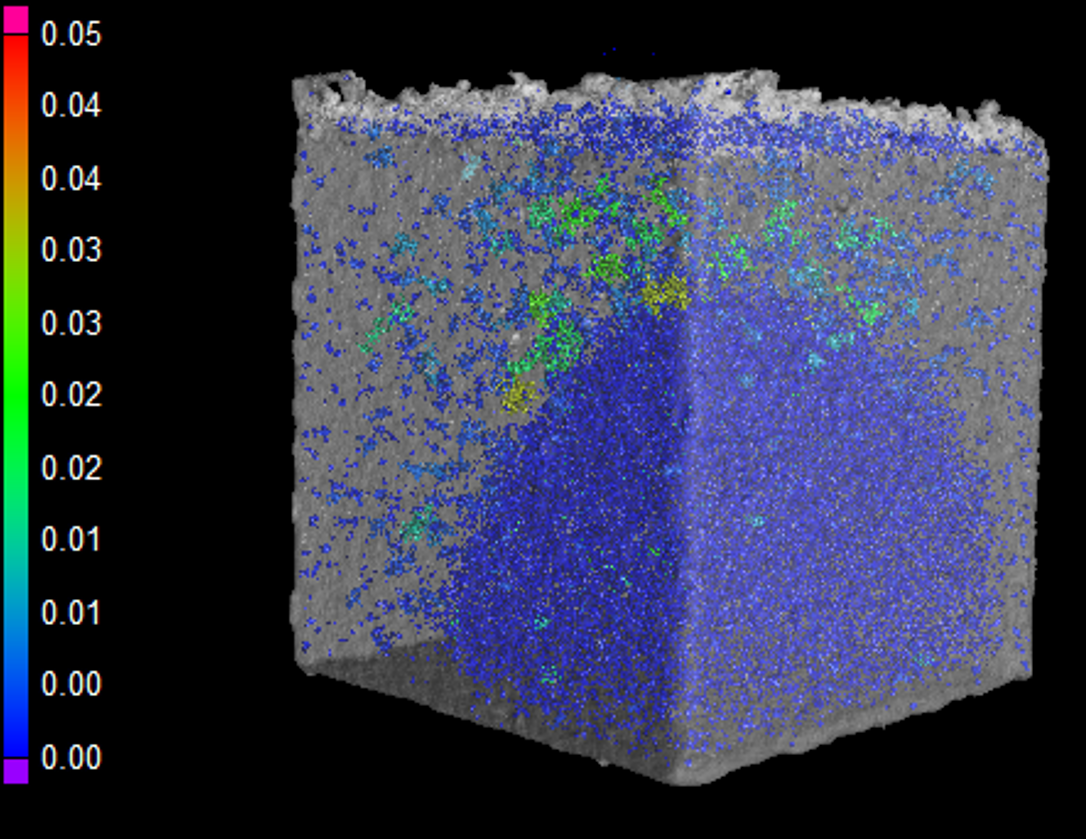

Computed tomography uses X-rays to create detailed cross-sectional images of the material. These images are combined to create a three-dimensional model that enables the internal structure to be analyzed precisely. CT offers a very high resolution and can make even the smallest defects visible. This level of detail is a major advantage of computed tomography.

Another advantage of CT is its versatility. It can provide a complete three-dimensional representation of the material, which enables comprehensive analysis. This is particularly useful when it comes to examining complex structures or areas that are difficult to access.

However, computed tomography also has its disadvantages. It is significantly more expensive than ultrasonic testing, both in terms of purchasing the equipment and carrying out the tests. This method is also limited in terms of sample size, meaning that it is only possible to test a sample section of bar stock, but not the entire bar. The creation and analysis of CT images is also more time-consuming. The use of X-rays also requires special safety measures to protect the health of the operators.

Kombination der Methoden und Kosteneinsparungen

Die Kombination von Ultraschall- und Computertomographie-Prüfungen können die Vorteile beider Methoden nutzbar gemacht werden und gleichzeitig die Nachteile minimiert werden. Ein möglicher Ansatz ist die Verwendung der Ultraschallprüfung als erste Screening-Methode, um potenzielle Defekte schnell zu identifizieren. Anschließend kann die Computertomographie gezielt eingesetzt werden, um diese Defekte genauer zu untersuchen und um diese zu identifizieren.

Durch die Vorselektion mit der Ultraschallprüfung können nur die verdächtigen Bereiche mit der Computertomographie untersucht werden, was die Anzahl der teuren CT-Scans reduziert. Dies führt zu erheblichen Kosteneinsparungen, da nicht das gesamte Material mit der CT-Methode geprüft werden muss. Zudem reduziert der kombinierte Einsatz den Gesamtaufwand an Zeit und Ressourcen, da die schnelle Ultraschallprüfung die zeitaufwändige CT-Prüfung ergänzt.

Die Kombination der beiden Methoden erhöht auch die Genauigkeit der Qualitätsprüfung, da die Stärken beider Methoden genutzt werden. Die Ultraschallprüfung kann schnell und kostengünstig große Mengen von Material untersuchen, während die Computertomographie eine detaillierte Analyse der identifizierten Defekte ermöglicht. Insgesamt bietet die Kombination von Ultraschall- und Computertomographie-Prüfungen eine effiziente und kosteneffektive Lösung zur Qualitätsprüfung von Metallstangenmaterial oder anderen Halbzeugen und Produkten, die sowohl die Detektionsgenauigkeit als auch die Wirtschaftlichkeit optimiert.

Newsletter registration