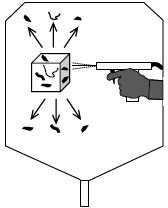

Air jet extraction

Analytical method for quantitative description of component cleanliness of liquid-sensitive components (according to VDA 19.1 / ISO 16232:2018)

Application and method of manual air extraction

Extraction by means of air jet can be an alternative to rinsing extraction for liquid-sensitive components and is suitable, for example, for testing the cleanliness of electronic components, for individual parts of the intake tract of engines that cannot be flowed through or also for logistics packaging such as blister packs, small load carriers.

The process requires a completely closed extraction cabinet with access possibilities and a compressed air connection. The components in the extraction cabinet are manually blown off with a jet of compressed air. The particles are thereby deposited on the liquid-wetted walls of the cabinet, and are subsequently rinsed off the walls by liquid extraction and transferred to an analysis filter. After blowing off, the component can be removed dry from the extraction.

The procedure is basically similar to the analysis with liquid

- The particles (residual dirt) are collected on a filter and analysis - as required - by gravimetry, microscopy or elemental analysis characterized.

- The measurement result is independent to a large extent by the design of the extraction procedure.

- Calibration and capabilities of measuring instruments used to determine to a large extent the result of to be determined cleanliness values.

Newsletter registration

You find more information about our technical newsletter here!